Kansas OSHA Training Requirements | 10 and 30 Hour Courses

For those working in the Kansas construction, manufacturing, or oil and gas industry, the question...

Posted On: March 06, 2025

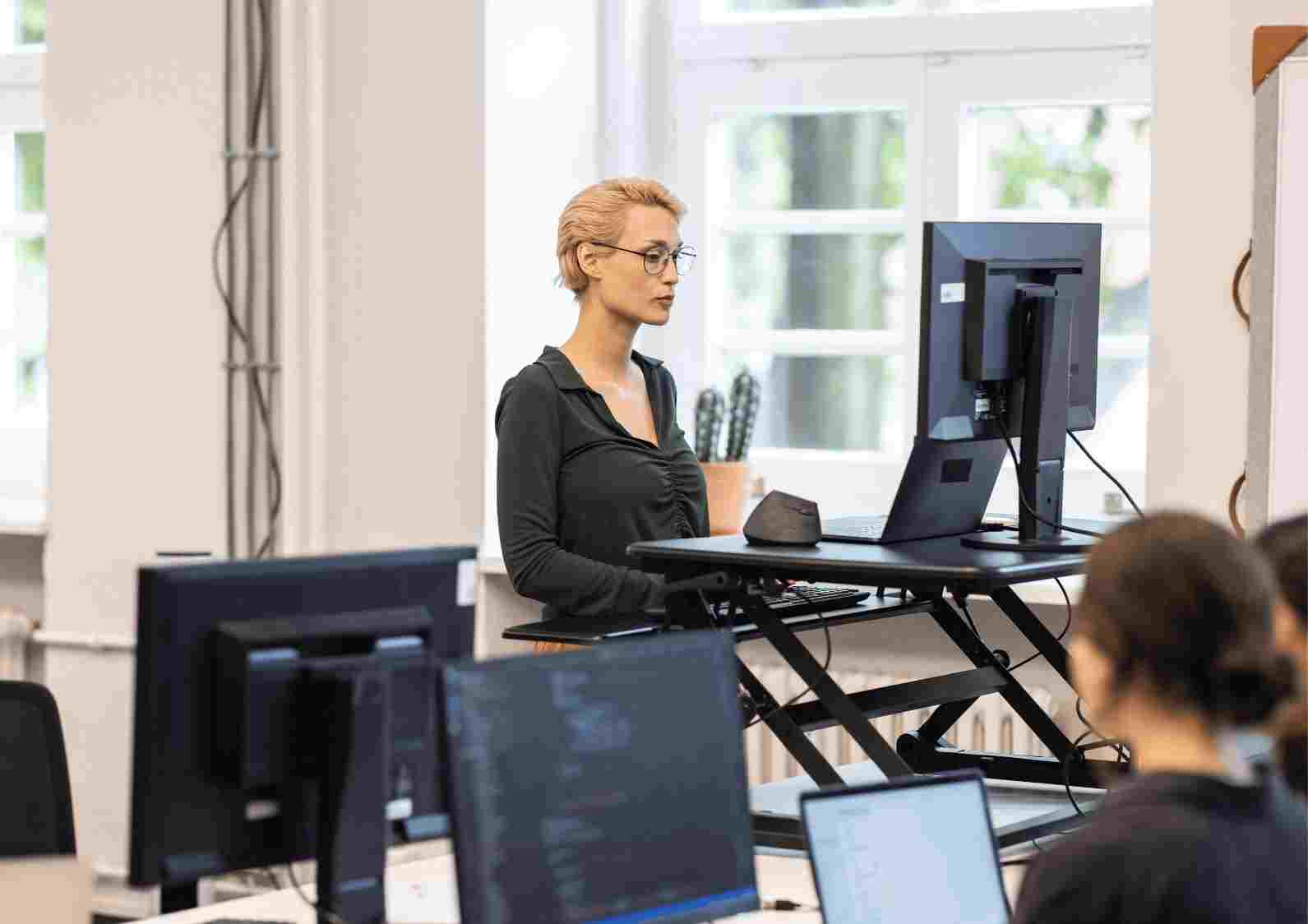

Industrial ergonomics focuses on designing workplaces, tools, and tasks to match workers' capabilities, reducing strain and improving efficiency. It helps prevent injuries from repetitive movements, awkward postures, and excessive force. Applying ergonomic principles creates safer and more productive work environments.

Workers in industries such as manufacturing, construction, and warehousing face ergonomic hazards, including:

Implementing ergonomic solutions in the workplace offers several advantages:

Applying ergonomic principles improves working conditions and overall safety. Effective solutions include:

Industrial ergonomics improves workplace safety, reduces injury risks, and increases productivity. Identifying ergonomic hazards and applying practical solutions create a safer and more efficient work environment. These practices benefit both employers and employees, leading to long-term success.

For those working in the Kansas construction, manufacturing, or oil and gas industry, the question...

Suspended scaffolds are temporary work platforms that hang from secure anchorage points and are...

Supported scaffolds are temporary elevated platforms supported by structural members and used across construction and industrial...

Renewing a Site Safety Manager (SSM) certification in New York City is a regulatory requirement that keeps safety professionals current...

Many jobs in Colorado expose workers to fall hazards, electrical risks, machinery hazards, and...

Many Hispanic and Latino workers in the U.S. are employed in high-risk industries such as construction...