Kansas OSHA Training Requirements | 10 and 30 Hour Courses

For those working in the Kansas construction, manufacturing, or oil and gas industry, the question...

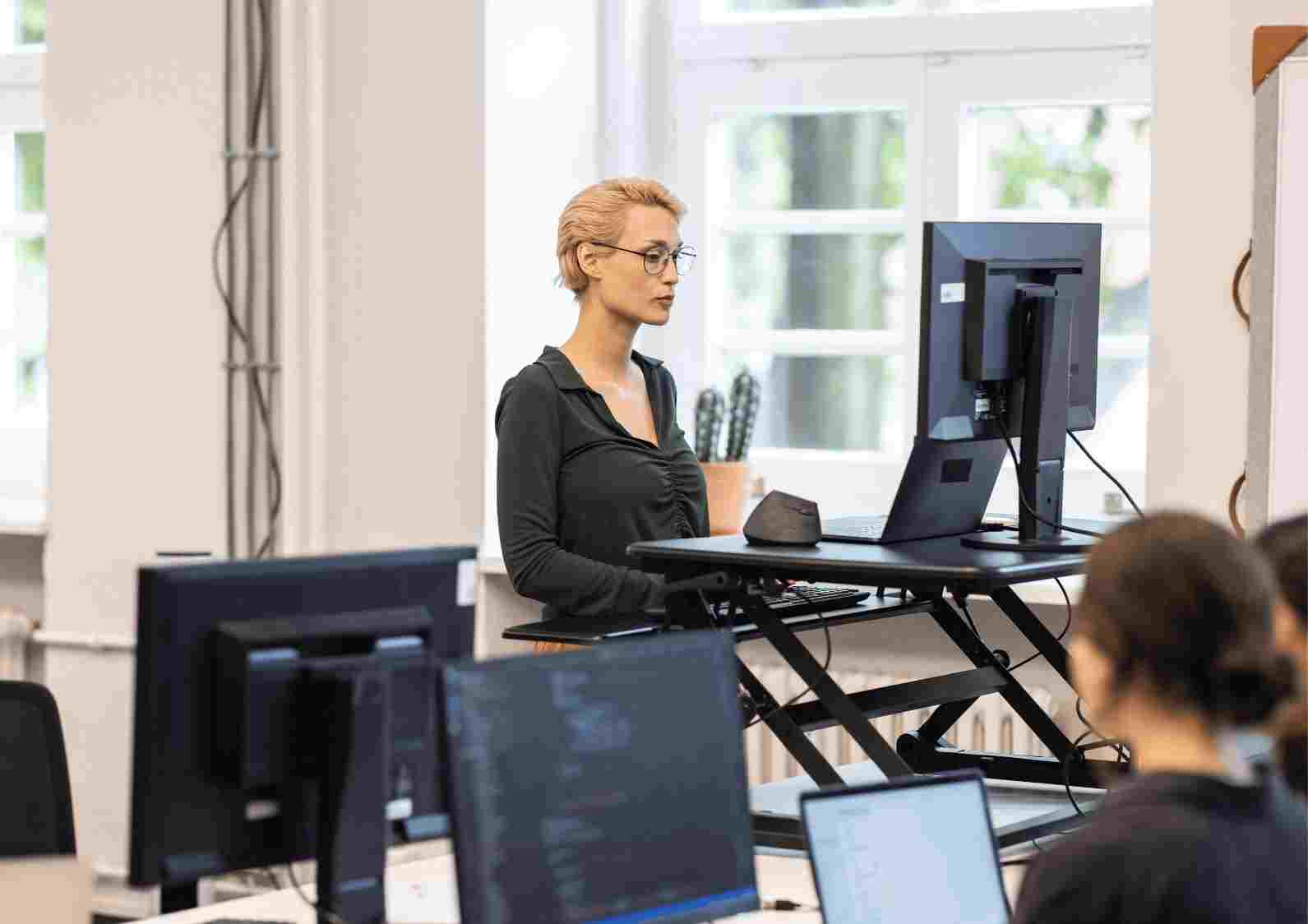

Industrial ergonomics is the practice of designing workplace environments that match the capabilities and limitations of employees. In simpler terms, it's about making workspaces more comfortable, efficient, and safe. It’s a discipline that considers several factors, such as physical stress and environmental conditions, to improve human performance and reduce the risk of injuries.

Musculoskeletal disorders (MSDs) can occur with excessive and repeated physical stress on the hands, wrists, elbows, shoulders, neck, or back.

Risk factors are the conditions that increase the likelihood of an injury.

The level of risk depends on how long, how often, and the level of exposure to these conditions.

It is the responsibility of the employer to assess the workplace to identify the jobs and activities that can potentially increase the risk of MSDs.

The following are the common risk factors:

Prevention is the best practice for any foreseeable work-related injury, especially when there are risk factors for MSDs. To keep workers from getting injured something at the workplace must improve. Hazard prevention and control should be implemented in the ergonomics plan.

Changes can be made to the jobs, workstations, equipment, and working environment to ensure the safety and well-being of the workers.

Engineering controls help design the workstations, tools, and equipment to better fit the worker, these controls are preferred over others because they make permanent changes that reduce and eliminate hazards at the source.

Engineering controls include:

Administrative control can also be implemented by the employer, administrative controls reduce the duration, frequency, or severity of exposure to a hazard by monitoring employees and keeping a schedule.

(Examples – rest breaks, job rotation, and job design)

If the hazards cannot be eliminated at the source, safe ergonomics work practices should be utilized.

Industrial ergonomics is imperative for creating workplaces that prioritize the health, comfort, and productivity of employees. By paying attention to signs of discomfort and understanding the factors that could lead to injuries, companies can take steps to protect their employees’ health. Implementing ergonomic solutions, such as engineering and administrative controls, not only reduces the risk of injuries but also increases morale and job satisfaction. Additionally, when a company takes the right measures for industrial ergonomics, it reflects positively on the company policies for employee health and well-being and ultimately, results in heightened productivity.

For those working in the Kansas construction, manufacturing, or oil and gas industry, the question...

Suspended scaffolds are temporary work platforms that hang from secure anchorage points and are...

Supported scaffolds are temporary elevated platforms supported by structural members and used across construction and industrial...

Renewing a Site Safety Manager (SSM) certification in New York City is a regulatory requirement that keeps safety professionals current...

Many jobs in Colorado expose workers to fall hazards, electrical risks, machinery hazards, and...

Many Hispanic and Latino workers in the U.S. are employed in high-risk industries such as construction...